Healthcare need? Try printing it

3D printing is transforming the medical industry.

Until about now, if you invented a tangible product and were planning on bringing it to market, chances are you’d need to find or set up a factory, complete with the equipment and production lines necessary to build the item. But soon, this approach to startup manufacturing might be more like “chances were” than chances are, all thanks to strides in 3D printing.

By laying down and fusing thin layers of plastic, metal or cement to produce a thing, 3D printing makes a digital creation into a physical one. More and more manufacturers – from shoe companies to the aerospace industry – have deployed this technology to accelerate their production processes, reducing both time and cost. And now, some of 3D printing’s most notable potential is showing up in the medical field.

Med companies are already 3D printing their way out of longstanding problems:

- According to the Journal of the American Academy of Orthopedic Surgeons, 3D printing has significantly upgraded bone and cartilage restoration, with the potential to completely transform the treatment of debilitating musculoskeletal injuries. For procedures like knee implants, patients can now receive a 3D-printed replica of their own knee instead of an “off the shelf” joint, for a perfect for. 3D printing is improving not only the fit and function of various prosthetics, but also their accessibility and affordability.

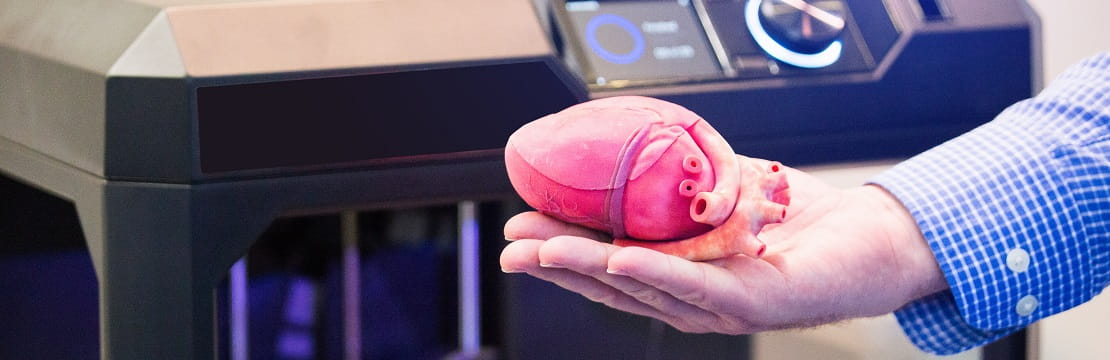

- 3D-printed anatomical models can be more accurate and detailed than previous models, empowering surgeons to practice on realistic bodily reproductions to better prepare for procedures. Better models mean better patient outcomes and shorter procedures.

- Who would’ve thought you could print devices like forceps, clamps and retractors? 3D printing technology is helping to speed development and production of much-needed precision medical equipment, alleviating supply chain issues along the way.

Next on the horizon is organ bioprinting, which could completely change the game for transplants. It’s no wonder more hospitals are expected to make the significant financial investment in 3D printing in coming years. They’re finding that the benefits of in-house 3D printing far outweigh the costs, especially given the aging population’s rising demand for the services 3D printing can make faster, better or both.

Sources: aha.org; cnn.com; investopedia.com; med-technews.com